We normally ship our products with DAP conditions.

DAP (Delivered at Place) is an Incoterm that replaced the former term DDU (Delivered Duty Unpaid). DAP transactions require the seller to arrange and pay the transportation of the goods to a place designated by the buyer, and the buyer to pay import duties and taxes on arrival of the goods.

Previously we released a long list of the import taxes for all counties here:

https://bartokdesign.com/9-faqcomment/import_taxes.php

But while the import taxes for wooden products are free (or very low) for most of the countries, please do remember you will also have to pay VAT and may be required to pay other charges (security fees, port fees, inspection fees etc.)

There is a great site that allows you to do the (approximate) calculation of the fees necessary.

(UPDATE 2020.11.21 : the previous tool ceased to supported for free so I found a new one)

https://www.simplyduty.com/import-calculator/

note that “simplyduty” is a third party not related to us.

Bartok design should not be held responsible for any mistake/incongruity in the calculation.

Note that the 1st calculation is free, you will have to purchase a credit if you need to repeat the operation.

Use the following parameters:

Importing from: Japan

Importing to: (your country)

Shipping method: Freight

Insurance cost: 0 (zero, we already included it in the shipping cost)

Product description: Wooden Bathtub

Product category: Jacuzzis & Spas

HS code: 4421.90

Note:

I wrote about this point several times, why do we use the DAP terms?

Answer:

Our invoice includes all the fees that we can be aware of. Cost of the products, shipping and delivery charges. The local taxes and customs processing fees may vary from case to case (the customs may require an inspection, etc.) so we prefer to keep them separated and having the client paying directly the net amount at the same time as they sign the paperwork for the customs.

If we had to include the taxes in our invoice we would have 2 options:

1) Bill the minimum amount as per our forwarder`s most optimistic calculation and bill you the difference in case the shipment incurred in additional fees.

2) Bill you an amount which takes into consideration the risk for additional fees. This would become more expensive for you.

We think that option 1) is cumbersome and option 2) is unfair, this is the reason why we use the DAP terms.

Please note that we can also ship EX-WORKS terms (you appoint your own forwarder who will take care of the whole shipping process. In this case our invoice will not include any shipping cost.)

Also if you prefer, we can ship to the airport or port CFS terminal (without delivery).

You will appoint a local forwarder to take care of the customs procedures and delivery to site.

Please contact me if this explanation is not clear or for any problem/question.

-> japan@bartokdesign.com

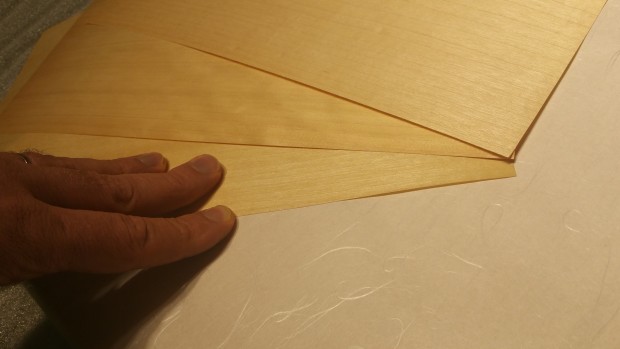

Click on (more…) here below to see the mesmerizing inside of the tub. Can you imagine the aroma?

Click on (more…) here below to see the mesmerizing inside of the tub. Can you imagine the aroma?