function + minimalism

Within a Japanese soaking tub, we can find represented many concepts of the Japanese way of seeing the world. Complex details, multiple functions, technological inventions, influential styles and even historical conflicts can be all present, in a perfect balance, in the apparently simple line of an invisible wood joint.

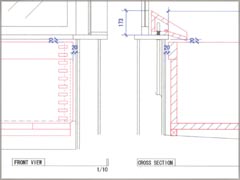

in Japan, wood CRAFT is synonymous with ART ->