bartok ofuro featured in AD!

We were featured in AD!

Click on the button below to see other pages.

(more…)

information about our activities, community, new products, culture etc.

We were featured in AD!

Click on the button below to see other pages.

(more…)

With more than 24hours left, we reached the funding goal for the hinoki aroma cards campaign!

I was prepared to boil to the last minutes begging for help but a kind soul saved me from a possible heart-stroke by pledging a hefty 300 USD!

Here is the message I received:

Hello Iacopo,

Have just made your $2000 work for you on the Indiegogo site.

Let me know how it goes…. and if you need any further help.

I really am looking forward to seeing and smelling the final product.

It was an experience of overwhelming joy!

I corresponded before with him but never met in person.

Nevertheless, he is treating me like a friend, helping me even if he does not share my purpose, just because he knows it is important to me.

I hope I will have the chance to return the favor very soon!

Thank you also to the 60+ people who believed in the project and made a pledge.

I should be able to ship the cards around the end of march.

A special thanks goes also to D. who made several small contributions.

She made one more order few hours ago and added:

I just pledged 15 USD and, purchased an additional set…

I want you to be successful!

This is a wonderful idea.

It was exciting to have so many people believing in the project!

It was also very fulfilling that even some who did not believe in the project contributed anyway.

Thank you all and keep your expectations high! The hinoki aroma cards will be amazing!

Two great, palpitating, exciting news:

Mainly with the purpose of promoting the hinoki aroma cards campaign, I started the official bartokdesign instagram page! For all instagram fans please visit the link below:

https://www.instagram.com/bartokdesign/

alternatively, link to your instagram account and look for the user: #bartokdesign.

Please share the images of the aromacards! The success of the campaign depends on you.

Second news:

Update about the indiegogo campaign: AAAAAAgh!!!

We are almost there but there are only 3 days left. I still need to collect 500 US$ (25%).

Please share the link below. Your help is crucial!

https://igg.me/at/hinoki-aroma-cards

Thank you and All the Best//

iacopo

The owner of a lovely hinoki tub (not ours) in front of a window decided to replace it after 10 years. The bottom shows some signs of rot even if altogether the tub appears very well maintained.

Probably the drain did not have a proper gradient and apparently it is not draining completely.

Taking advantage of the renovation they will also probably create a tiled ledge on one side of the ofuro to make it easy to sit on the border before spinning the legs and enter inside. This way they will be able to use the tub safely even when they become elderly.

Because the tub is close to a window and may be seen from the outside, we applied the copper apron on both sides.

Click on (more…) here below to see the mesmerizing inside of the tub. Can you imagine the aroma?

Click on (more…) here below to see the mesmerizing inside of the tub. Can you imagine the aroma?

Also, you will find the measurements/specs and a note about “flip top” drains. (more…)

The “hinoki aroma cards” campaign had a slow start but is picking up and I am now hoping we can reach the goal! See -> https://igg.me/at/hinoki-aroma-cards

We are 37% funded but have only one week left… Please spread the word!

Here below I am reporting a mail exchange I had with a fellow “japanese lover” who kindly replied to my newsletter. I think that many people feel uneasy about “crowdfunding” all together. I would like to hear everybody`s opinion about!

Question:

Hello Iacopo,

You are a very busy man….

I see your mails I see the info but I am not understanding what you are

doing?

You need venture capital for the new aroma cards from what I understand.

What market is there for the cards ? Where I am based in *****, I do

not see one, Therefore I would like to know more.

Please give me a short 1 paragraph of what you envisage.

Thanks for response when you can.

Kind regards,

*****

My answer:

Dear *****,

Thank you for your interest.

Crowdfunding is a new (not so new anymore…) system.

It is not only for raising capital. I am doing this project on indiegogo mainly for 4 reasons:

1) it helps me to promote the project (and my brand) thru social media and newsfeeds. Promoting a “product” may feel pushy but promoting a “project” is more interesting and creates involvement.

2) it helps me to study the market needs. By developing a product thru the advice and ideas of the end users, I end up with a more evolved and better targeted product.

3) if I get the campaign funded, the product itself will be more convincing as it could win the heart and obtain the commitment from many people.

4) ultimately, it helps me to broaden my avatar. I am devoted in helping the traditional crafts (not with donations, but with a new market for their skills) + I believe our society needs a more human and sensorial culture.

My activity in the production of wooden bathtubs helps me progress in both missions. But japanese crafts is not only ofuro bathtubs and I am interested in exploring new markets.

I think there is a huge market for motivational message cards.

https://www.google.co.jp/search?q=motivational+cards&ie=utf-8&oe=utf-8&client=firefox-b-ab&gfe_rd=cr&ei=UEV-WJ2cG6fU8AeGm6vgCg

Additionally hinoki cards allow you to bring always the aroma with you!

Also they are more resistant and noble than paper.

This is my thought.

I would appreciate to hear your opinion!

All the Best//

iacopo

How about your opinion? Please comment below!

Please get involved in the campaign here: https://igg.me/at/hinoki-aroma-cards

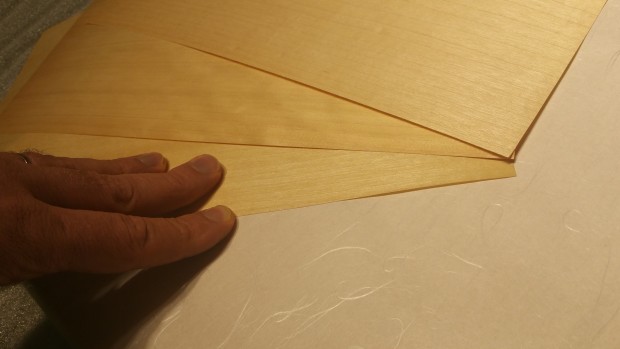

On the product development side, I am experimenting some samples of different cuts of veneer (sliced, rotary cut) etc. and washi paper. I will try which ones absorb and retain the aroma oil better.

Also about this, please check the indiegogo page for more updates.

(Photo courtesy of Simon Wearne)

Being an apostle of japanese ofuros and traditional woodworking technique enabled me to become acquainted with other fellow japan-lover “gaijins”. I correspond with Leonard Koren, Ricky Swaczy and Bruce Smith. I also have the honor of knowing the work of Douglas Brooks: a builder (or I should say “The builder”) of japanese boats.

The making of japanese bathtubs originates directly from boat building. The sawing technique, all the joinery and details (such as the use of copper plates or wood skin) are borrowed straight from the “funa-daiku” (boat carpenter) repertoire.

(Photo courtesy of Douglas Brooks)

Brooks resides mostly in USA but travels often to Japan. He is due to come on january 10th in Takamatsu to build a boat for Ritsurin Park. Then he is planning to build a boat for a museum in Gifu prefecture in may.

I hope I can catchup with him.

Meanwhile, if you are interested to have a specific information or have a project that may require a japanese traditional boat, please let me know.

Here below are some links to Douglas works, photos and book.

http://www.douglasbrooksboatbuilding.com

http://blog.douglasbrooksboatbuilding.com/

www.instagram.com/douglasbrooksboats

(Photo courtesy of Douglas Brooks)

This card consists almost entirely from material I received from a client I consider like a dear friend.

I especially like the phrase that life is precious and every moment should be lived “consciously”. The more “deliberately” you experience and feel these moments the more fully (= happily) you will enjoy this year and the years to come!

I am dedicating you also two other yo-ji-juku-go idiomatic phrases that contain facets of the same concept:

★ sho-gyou-mu-jou: all things are in flux, nothing is permanent

★ mei-kyo-shi-sui: (be) serene as a polished mirror and still water

Of course you can find the two quotations in form of hinoki wood aroma cards.

Check the indiegogo campaign here: https://igg.me/at/hinoki-aroma-cards

Again, happy new year and may the 2017 bring you one step closer to the realization of your dreams!

iacopo torrini

Our client R. sent us more pictures of his superb house in Apollo Bay, Victoria.

Apparently it is available as a kind of Air B&B so if you are in the area you may want to experience the house with great open views and the japanese bathtub!

http://www.greatoceanroadholidays.com.au/accommodation/2064

More pictures below

(more…)

With the help of many advice and insight I received thru friends and comments by mail and thru the google survey I think our aroma cards took the right shape!

This super-seeds the previous posts.

1) for this edition, I will focus on japanese idiomatic expression “yojijukugo”

2) 6 cards make one set (priced as 5 cards so one card is free. All old perks will be upgraded.)

3) 2 sets are available. It is also possible to have 6 cards with the same message. Let me know.

4) To avoid accidents the corners are rounded (5mm radius)